Modern Methods of Construction

Modern Methods of Construction (MMC) refer to innovative and efficient techniques for constructing buildings and infrastructure that deviate from traditional on-site construction methods. MMC involves the use of advanced technologies, off-site manufacturing, and standardized components to streamline the construction process and enhance productivity, quality, and sustainability. Here are some examples of modern methods of construction:

1. Off-site manufacturing: This method involves constructing building components, such as walls, floors, and roof panels, in a factory-controlled environment. These components are then transported to the construction site for assembly. Off-site manufacturing allows for greater precision, quality control, and speed of construction.

2. Prefabrication and modular construction: Prefabrication involves manufacturing entire sections or modules of a building off-site, which are then transported and assembled on-site. Modular construction takes prefabrication a step further by creating standardized modules that can be combined or stacked to form larger structures. This method reduces on-site labor requirements and construction time.

3. 3D printing: Additive manufacturing, or 3D printing, is an emerging method of construction that involves creating three-dimensional objects by layering materials based on digital models. In construction, large-scale 3D printers can create structural components, such as walls or columns, using materials like concrete. 3D printing offers design flexibility, reduces waste, and enables complex geometries.

4. Advanced materials and systems: MMC involves the use of advanced materials and systems that offer superior performance and sustainability. For example, high-performance insulation materials, energy-efficient windows, and renewable energy systems can be integrated into the construction process to enhance energy efficiency and reduce environmental impact.

5. Lean construction techniques: Lean construction focuses on maximizing value and minimizing waste throughout the construction process. It involves efficient planning, coordination, and communication among project stakeholders, as well as the adoption of just-in-time delivery practices to reduce inventory and improve productivity.

The adoption of modern methods of construction can lead to numerous benefits, including faster construction times, improved quality control, cost savings, reduced environmental impact, enhanced safety, and increased sustainability in the built environment.

Darkin Architects have experience and knowledge of a range of MMC systems that put us in a strong position to support your MMC project.

BECO Wallform

Insulated Concrete Forms (ICF)

Advantages include:

- Rapid construction time

- Ability to construct during colder weather

- Improved air-tightness

Emmedue Building System

A variation on ICF, this system differs from others as it utilizes panels rather than blocks. According to the manufacturer, this can cut construction time by as much as 40% which can in turn provide cost savings.

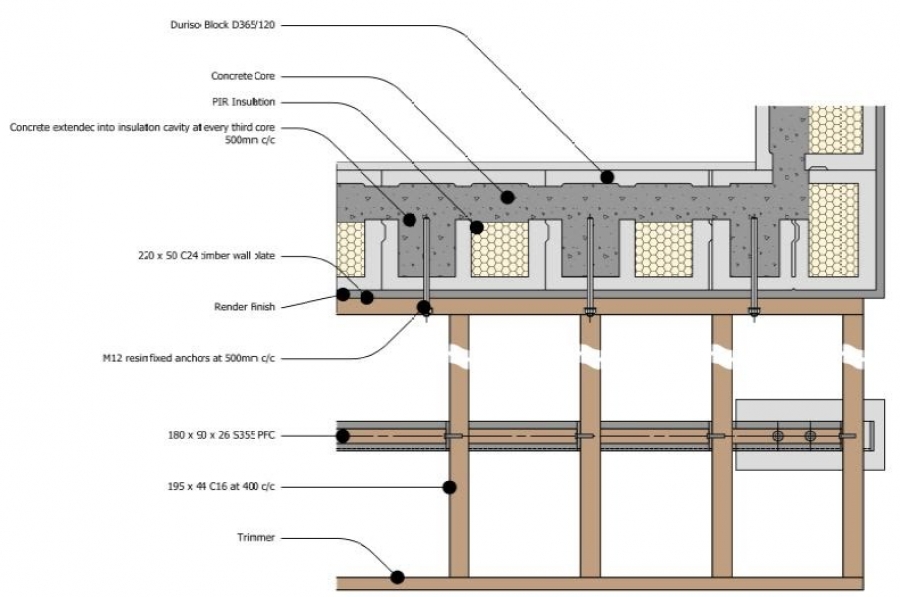

Durisol

Insulated Concrete Forms (ICF)

Above: Construction detail from New Home in Swansea, designed by Darkin Architects to be constructed from ICF.

Very similar to the Beco Wallform, this product is made from a wood product.

Advantages include:

- Rapid construction time

- Ability to construct during colder weather

- Improved air-tightness

- Simple cutting method

- Excellent BREEAM rating

Timber Frame

Above: Timber Frame Home under construction in Ammanford

Timber frame construction may not be as rapid to construct as ICF buildings, but is still a relatively quick way to construct.

Advantages include:

- Quick Construction

- Typically Cheaper than ICF

- More familiar form of construction to most building contractors